3D Printing Technician

Course Description:

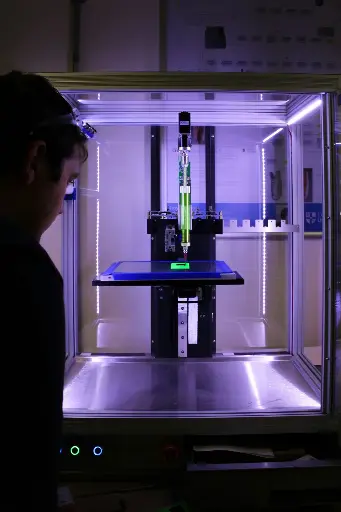

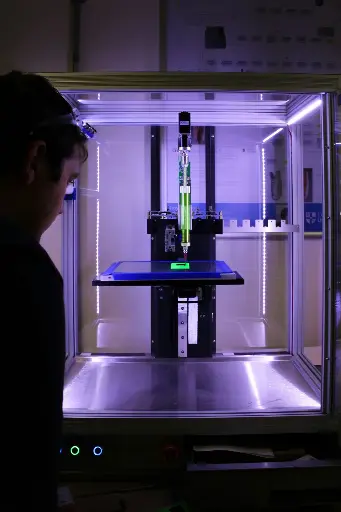

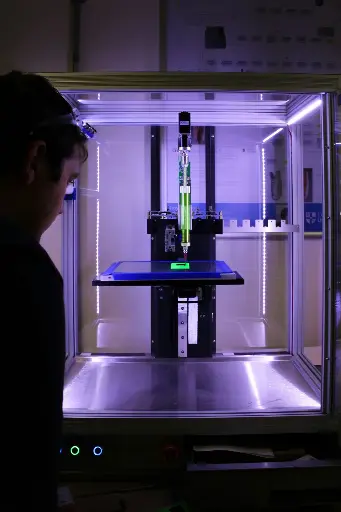

Unlock the full potential of Fused Deposition Modeling (FDM) 3D printing with our comprehensive course designed for makers, designers, engineers, and hobbyists. Whether you're a beginner or looking to refine your skills, this course offers a deep dive into the fundamentals, advanced techniques, and practical applications of FDM 3D printing, with a special focus on optimizing your workflow using Bambu Labs/Orca Slicer.

What You'll Learn:

- Fundamentals of FDM 3D Printing: Understand the core principles, history, and key terminology of FDM technology, and explore how it compares to other 3D printing methods like SLA and SLS.

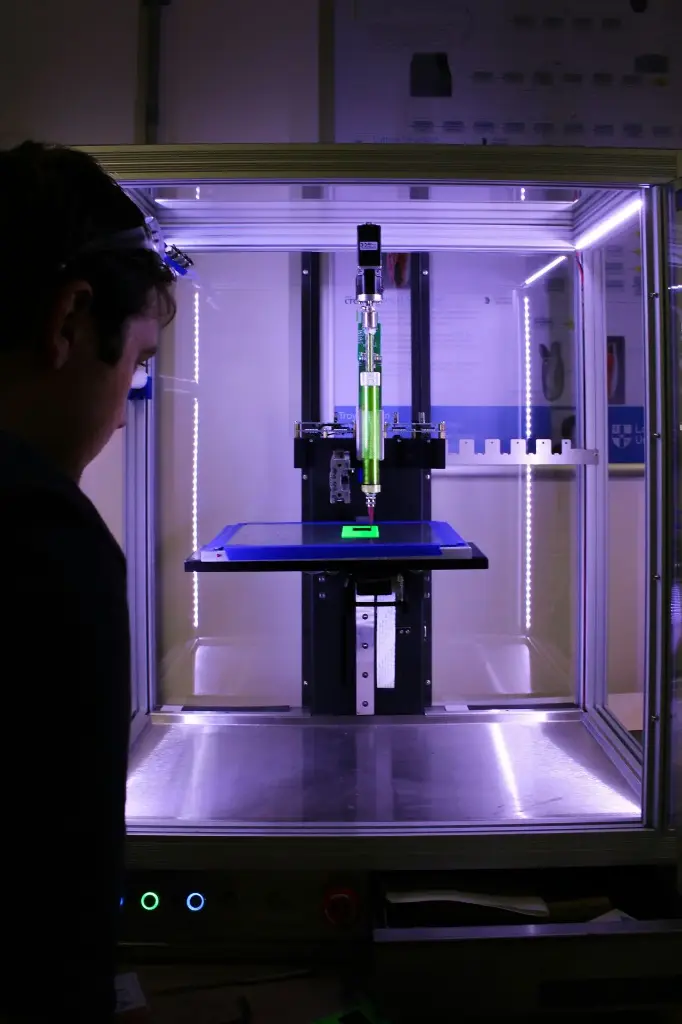

- Printer Hardware & Technical Aspects: Gain hands-on knowledge of FDM printer components, including hotends, extruders, nozzles, and motion systems. Learn essential maintenance, calibration, and safety protocols to keep your printer running smoothly.

- Slicer Software Mastery: Dive into the advanced features of Bambu Labs/Orca Slicer, including adaptive layer height, dynamic support generation, and material-specific profiles. Discover how to optimize slicer settings for different materials and project requirements.

- Troubleshooting & Problem Solving: Develop the skills to diagnose and resolve common 3D printing issues such as layer shifting, poor bed adhesion, stringing, and thermal runaway.

- Real-World Applications: Explore case studies and simulated scenarios that demonstrate how FDM 3D printing is used in industries like medical prototyping, automotive design, and art.

Course Structure:

The course is divided into 7 modules, each combining theoretical knowledge with practical exercises. You'll engage in group discussions, hands-on lab sessions, and real-world case studies to reinforce your learning. By the end of the course, you'll complete a final assessment and reflective journal to consolidate your skills and prepare for future projects.

Who Should Enroll:

- Beginners looking to build a strong foundation in FDM 3D printing.

- Intermediate users seeking to enhance their technical skills and slicer software expertise.

- Professionals in design, engineering, or manufacturing who want to leverage 3D printing for prototyping and production.

- Hobbyists and makers interested in exploring the creative possibilities of 3D printing.

Course Outcomes:

By the end of this course, you will:

- Have a comprehensive understanding of FDM 3D printing technology and its applications.

- Be proficient in operating, calibrating, and maintaining FDM printers.

- Master advanced slicer settings to optimize print quality and efficiency.

- Develop troubleshooting skills to overcome common printing challenges.

- Be equipped to plan and execute complex 3D printing projects with confidence.

Why Choose This Course?

This course is more than just a technical guide—it's a hands-on

learning experience designed to empower you with the skills and confidence to

tackle any 3D printing project. With a focus on real-world applications and collaborative

learning, you'll leave the course ready to innovate and create with FDM 3D

printing.

Join us and take your 3D printing skills to the next level!

Prerequisites: 3D Printing History

Duration: Self-paced with hands-on lab sessions and group discussions.

Tools Required: Access to an FDM 3D printer and Bambu Labs/Orca Slicer software (trial versions available).

Enroll today and start your journey toward mastering FDM 3D printing!

| Responsible | James Larsen |

|---|---|

| Last Update | 04/28/2025 |

| Completion Time | 5 hours 35 minutes |

| Members | 5 |

3D Printing - The Future is Now!

Introduction

View all

R&D Papers

View all